Originally posted by xoc:

There does appear to be a design flaw in that setup.

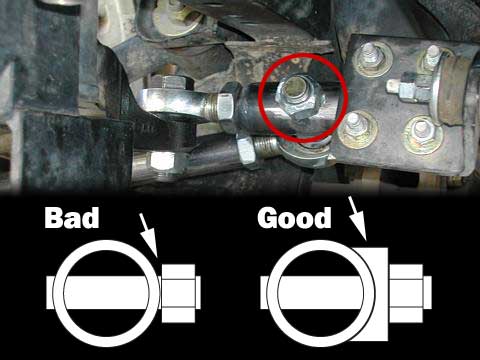

Where the tie-rod attaches to the relay rod, the nut is simply tightened onto the rod. This creates a very tiny mating surface, which could break. The rod should have a boss on it like the image below.

Good call Ian....and I'll take it a step further. Even with Ian's suggestion the nut will loosen and the bolt will begin to show play (slop). I would drill a slightly larger cross bore hole (where the bolt that Ian points out is located) and insert a sleeve. That sleeve would then be welded into place and a end thread only bolt could be used.

As it appears now the bolt to "tube" contact is less than ideal. With a end thread bolt and a sleeve with tight tolerance to the smooth portion of the bolt, the contact is more even and distributed.....smoother operation.